A new silica standard went into effect in the United States on September 23rd, 2017. We discussed with Joel Guth from iQ Power Tools and here's what he had to say.

The Occupational Safety and Health Administration (OSHA) issued a new rule to protect workers from respirable crystalline silica in 2017. Since then, inspectors have been out on job sites looking for dust clouds.

Silica dust can do irreparable damage to your lungs and can cause life-threatening illnesses like silicosis and chronic obstructive pulmonary disease (COPD). Click here for an OSHA silica fact sheet.

Here’s a video demonstrating how silica penetrates and damages the lungs:

OSHA and safety experts recommendations

- Eliminate the hazard

- Substitute the material on the site that contains silica with another. This is not an option for hardscapers.

- New engineering controls, like wet-cutting, tools equipped with a vacuum system or local area ventilation. Wet-cutting is very messy. The slurry gets on the skin, clothes, all over the project, stains the products and often causes safety problems. Tools with an integrated vacuum system, filter system and dust containers eliminate the hazard right at the source of the cut, capture the dust and contain it. In a previous article, we compared the two technologies: dry cutting with dust control vs wet cutting.

The advantages of vacuum technology are no clean up and staining of the units, it's less expensive, it helps to recruit and retain good people and the system cools the blade, so it prolongs the life of the tool.

- Administrative controls: Coordinate and control the workers to place them away from where the dust is generated and monitor the air quality, for example. This means setting up a cutting station far away from the rest of your crew on site.

- Use of Personal Protective Equipment (PPE): PPE, like attenuators, respirators and safety glasses, are the last line of defense against hazards, and OSHA says that they can’t be used for an everyday occurrence. The use of respirators requires workers to learn the Respiratory Training Program, which is a book of more than 100 pages and is very difficult to implement.

The silica standard helps workers to know what the solutions are, explains how to put together and implement a silica exposure control plan and how to teach, train and educate people.

Eliminating dust provides better environment for the workers and helps them see what they are doing because they are not blinded by a cloud of dust. Who would not want to work in a cleaner and safer environment?

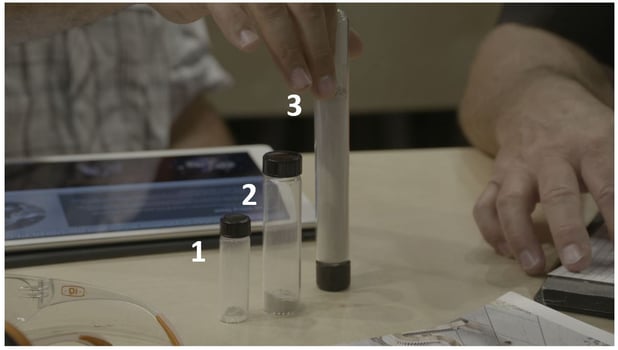

Dust amount comparison

Here's what each amount represents :

1 - Allowed silica amount for one week with the new standard

2 - One year of total dust exposure under the new standard

3 - Cutting one standard paver

A lot of people think the amount of silica inhaled on a job site isn’t a problem, but the above illustration proves that it is something they should be concerned about.

Fines

Since September 23rd, 2017, if an inspector sees someone working in a cloud of dust, here are the fines:

- First offense: 7,500$ per person per day. For example, if we take a crew of 4 people, it will cost 4 x 7,500 = 30,000$.

- Second offense with the same company, even if it happens later or with a different crew: 75,000$ per person per day. For the same crew (4 people), the amount to pay is new 4 x 75,000 = 300,000$.

The first infraction could be enough to be the equivalent of your annual net profits, and the second, your entire business by not following the OSHA silica rule.

If you train your people, implement a good exposure control plan, teach it to them and educate them, buying new engineering controls will save you time and money.

GET MORE INFORMATION ON CHANGES IN YOUR INDUSTRY TODAY!