In this article, we compare segmental permeable pavement to porous asphalt. We cover each pavement type's respective background, composition, details of construction, maintenance, cost and longevity.

As new developments are constructed, the space allocated to vegetation diminishes. By consequence, the water cycle is disturbed, causing more flooding, erosion, sedimentation and general pollution.

This video summarizes the problems caused by increasing urban sprawl and how permeable pavement is a good storm water management solution.

Background

Permeable pavement has been around since 1980 in Europe and emerged 12 years later in North America. Porous asphalt was introduced in United States in the 1970s. They both can be used in a variety of soils and climates.

Non-porous asphalt vs porous asphalt

Composition

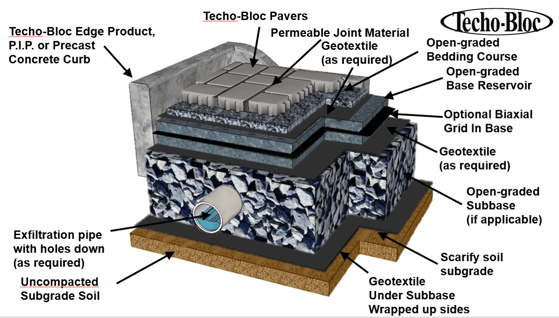

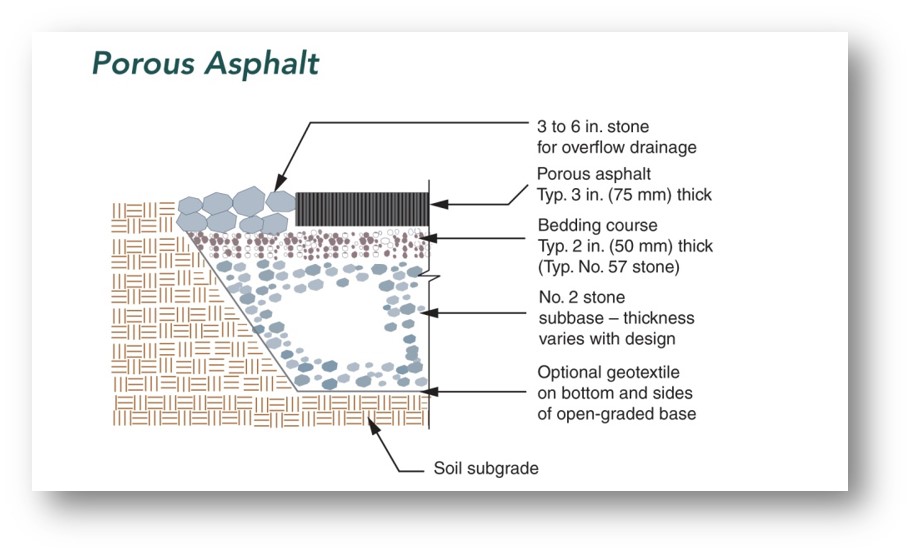

The base and reservoir of a permeable pavement are composed of large open graded aggregates. The system traps suspended solids, filtering pollutants from storm water. Porous asphalt is made of the same type of aggregates, but smaller.

Composition of a permeable pavement

Composition of a porous asphalt

Composition of a porous asphalt

The joints in a permeable pavement are filled with small-sized joint aggregates to allow water to pass. Their size varies between 1/8 and 5/8" (3 and 16 mm). There are no joints in porous asphalt.

Although the permeable surface areas are smaller than porous asphalt since the block is not permeable, but what’s around and under it is, the infiltration rates are very high and even well-worn systems can withstand most rainfalls.

Infiltration chart for all of our permeable products

Infiltration chart for all of our permeable products

Construction

The quality of our paving stones is consistent. They exceed all product standards (ASTM C936 and CSA A231.2), have a high compressive strength surpassing 8000 psi [55 MPa] min. and are durable over decades of freeze-thaw cycles.

Porous asphalt cannot be installed in freezing weather, and maintaining mix temperatures on site is critical to its lifetime performance. It requires a curing time of 24 hours prior to traffic, as opposed to permeable pavement, which can be installed in freezing temperatures and demands no curing time and is therefore ready for trafficking immediately.

Workers installing porous asphalt

We offer a wide range of colors and textures in our permeable pavement collection, while porous asphalt usually comes in black or shades of dark gray. Additonally, permeable pavements constructed using light colors absorb less heat, keep temperatures cool and they reduce the need for nighttime lighting, conserving electricity.

Maintenance

During winter, when the snows melts, it infiltrates into the permeable pavement, which reduces the need for plowing, salting and the risk of hazardous ice patches. When the pores of porous asphalt are saturated with water, the material can be damaged as the water freezes and expands.

Our high-quality concrete has no problem resisting the passing of time. It can be plowed like any pavement, and any damage can be easily addressed, due to its segmental nature. Just extract the damaged units, and replace them with other ones, as opposed to monolithic materials like porous asphalt. Small areas can be removed and replaced, but the repaired area will not match the surrounding surface. Its structural capacity will also be diminished.

Machine plowing a permeable pavement

Permeable pavement should be inspected regularly, vacuumed and swept. It’s important to remove accumulated sediment from the surface. If the aggregates get deeply clogged, they can be removed and replenished. Porous asphalt is not as flexible. Deeply clogged surfaces are difficult to restore. The surface should be power washed or vacuum swept to remove sediment and debris. Remember, the most important surface infiltration verification is visual observation.

Vacuum sweeper

Vacuum sweeper

Cost and longevity

Regarding installation and upkeep costs, porous asphalt is less expensive than permeable pavement. However, labor costs have a greater influence the job pricing than the material costs. Local materials, pavement area and contractor experience play their part. An increased expected life span of a segmental permeable pavement greatly decreases its lifecycle costs.