Our Prescott wall’s authentic sizes, shapes and textures create the most natural style wall available in the retaining wall industry. The process of building this retaining wall gets easier with modular construction. Here's exactly how to get it done.

As it is indicated in our Techo-Spec guide, the dimensional tolerance for Stonedge wet cast retaining wall units is: ± 3/16" (5 mm) for height and ± 1/2" (13 mm) for length and width.

During the installation, the heights of adjacent wall units will vary (usually, more than for a dry cast wall unit) providing a more realistic appearance of a natural stone wall.

For a Prescott retaining wall construction to go smoothly, anticipate a bit more labor consumption, so it’s important to plan accordingly.

We recommend building it in a modular pattern to increase productivity and provide a great look.

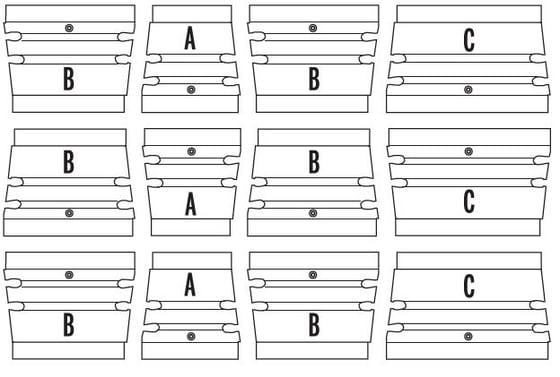

Building a Retaining Wall in a Modular Pattern

Modular construction requires 2.25’’ and 4.5’’ units.

Use alternating courses of:

- ABC/cba

- cba/ABC

- CA/ac

- ac/CA

- AB/ba

- ba/AB

- BC/ca

- cb/BC

- b/B

- B/b

For every alternating set of ABC/cba, use one BB combo to account for extra “B” units in the pallet.

Ratio to build modularly using both sizes should be 66% 4.5 units and 34% 2.25’’ units, or 2:1 4.5’’ to 2.25’’.

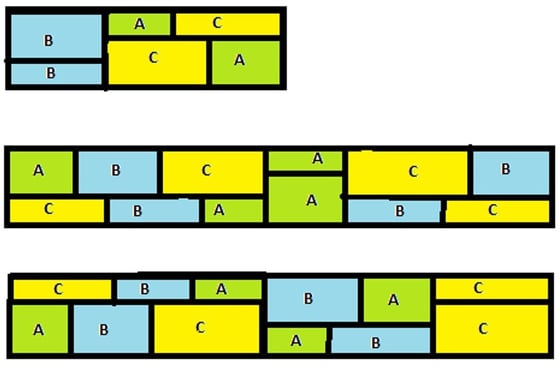

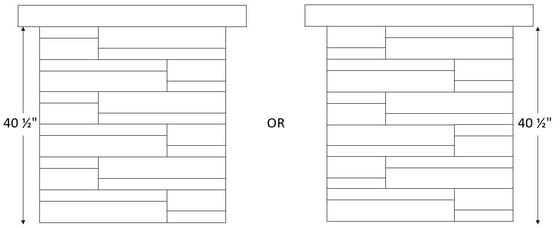

This image shows some examples of modular construction with Prescott Wall 2.25’’ and 4.5’’ units:

Avoid patterns that have too many 2.25’’ units stacked in one area. This will magnify the minor height difference.

This is a representation of how units are placed on a pallet:

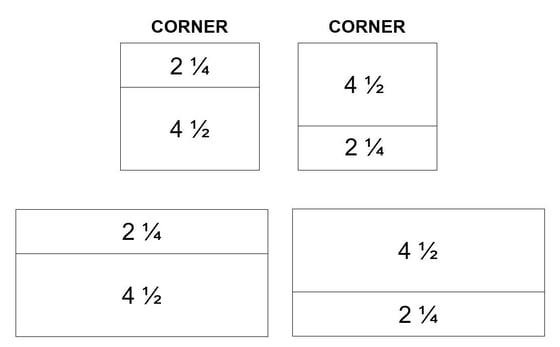

Modular Construction : Corners and Pillars

Corners need to be installed in 6 ¾’’ modules also to work with the wall.

Corner ratio is the same as block ratio: 66% of 4.5’’ Corners and 34% of 2.25’’ Corners, or 2:1 4.5’’ to 2.25’’.

This diagram presents an overview of corner options:

Here are two examples of modular pillars constructed like a wall:

BUILDING A WALL THAT NEEDS REINFORCEMENT, BUT CAN'T FIND WHAT YOU NEED IN THE TECHO-SPEC GUIDE?

CHECK OUT OUR