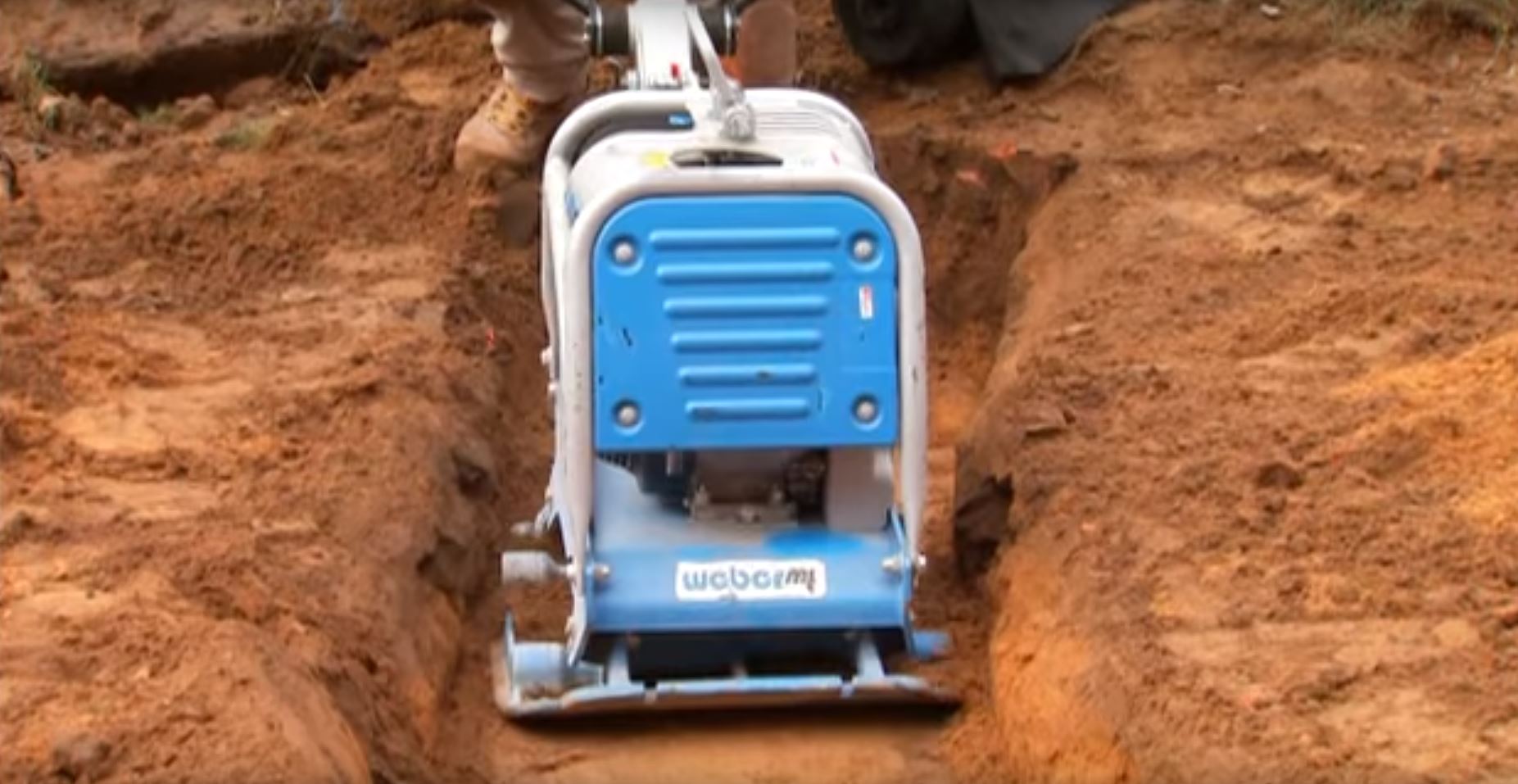

A lack of compaction is the number one reason for failure on hardscape projects. Here Paver Pete demonstrate options for compacting the soil subgrade in a trench.

There are a couple of criteria that need to be considered when choosing equipment to compact the soil subgrade in a trench.

- Size of the space

- Centrifugal force rating of the equipment

- Reversibility of the machine

- Type of soil to be compacted

Here are 3 types of compaction equipment we analyzed.

- 12,000-pound centrifugal force rated vibratory plate compactor

Its reversibility is perfect for compacting base material when we have more than 8-inch lifts.

In this situation, we have a very sandy soil, so we don’t need that much strength.

- 7,200-pound centrifugal force rated vibratory plate compactor

It is also reversible, so it improves productivity when we work in a trench.

- Amplitude-based compactor, also called a jumping jack

It would not be effective in an open area that has a sandy soil, but it works well in a restricted area like the trench we have here.

JOIN THE BIGGEST EDUCATIONAL EVENT OF THE LANDSCAPING INDUSTRY THIS WINTER AND TOGETHER, LET'S BUILD YOUR BUSINESS!